Biogas is produced as a byproduct of anaerobic digestion or by decomposition of organic wastes into methane and carbon dioxide. Effective utilization of biogas in fuel cell applications requires the removal of impurities such as sulfur (e.g., hydrogen sulfide, mercaptans, and disulfides) and siloxanes to prevent degradation of cell stacks and poisoning of the catalysts used in the fuel processor. The sulfur concentration in biogas can be very high (up to 400 – 15,000 ppmv) and the gas is saturated with water (~5-8% vol. H2O).

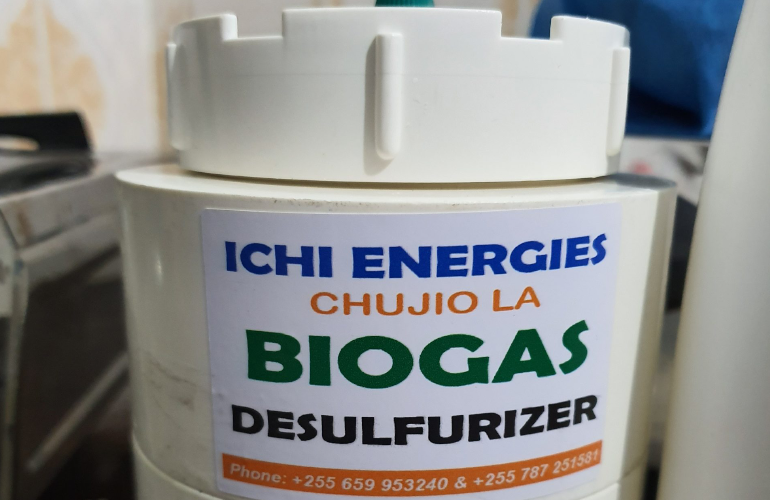

Thus, a desulfurizer is used to filter and purify the biogas produced by the plant.

Services We Provide

To guarantee smooth operation and complete safety of the Biogas plant, frequent or periodic inspection has to be done. This will ensure efficient production of Biogas and Organic manure daily and avoid any leakage of liquid or gaseous substances from the plant.